NEW! Powerful Nano Filtration with Unger's HydroPower® Nano See The Product

Green Commercial Cleaning Practices

Cleaning Products Supporting Conservation and Sustainability

Introducing green commercial cleaning practices is often easier said than done when you’re responsible for maintaining the health, cleanliness and safety of a facility and its occupants. Just look at the COVID pandemic as an example of how cleaning and disinfecting trends superseded environmental concerns. This challenge is especially true when you consider that environmentally friendly cleaning means much more than just using “green” cleaning products and incorporates conservation and sustainability goals as well.

For the commercial cleaning industry, implementing “greener” practices starts from the beginning with the equipment and tools that you source. Not all cleaning equipment can reduce the environmental impact of cleaning and disinfecting, but if you know what to look for, you can lay the foundation for success for if and when your facility ramps up its commitment to executing a greener way of cleaning.

Sustainability Considerations in Green Gommercial Cleaning

Although the Environmental Protection Agency (EPA) manages the Safer Choice program, which certifies products that contain safer ingredients for human health and the environment, as a facility manager or building service contractor, you can take a step back and evaluate the commercial cleaning equipment used. Specifically, you should consider your equipment’s use of:

#1. DISINFECTANTS

Does the equipment limit the use of disinfectants to areas where people are likely to encounter contaminated surfaces (e.g., bathroom fixtures, doorknobs, desktops, other high-touch surfaces)?

#2. CLEANING PRODUCTS

What, if any, cleaning solution is required as that can increase exposure to potentially harmful chemicals?

#3. WATER CONSUMPTION

How much water does the cleaning tool require as water has become an increasingly valuable global resource? Optimizing water use protects this resource and reducing energy consumption indirectly helps reduce greenhouse gas emissions .

Sustainability and Microfiber Cleaning Technology

A reusable, highly-effective material, microfiber is an eco-friendly alternative to disposable cleaning cloths and cotton counterparts, and it all starts with microfiber’s unique construction.

Microfiber is a synthetic fiber constructed of a super fine blend of polyester and polyamide or nylon. The finished microfiber product is made up of thousands of tiny strands that are each 10-50 times smaller than the diameter of human hair. When woven together these strands create a surface area covered with millions of spaces between the fibers to trap moisture, dirt and debris. With millions of microfibers brushing each other, the resulting static charge also works to attract dirt and germs.

Given microfiber’s natural ability to attract and hold contaminants, it requires fewer harsh cleaning chemicals to clean and disinfect a surface. By decreasing chemical use, microfiber makes a direct impact on air quality for both cleaning staff and building occupants, as well as on the surrounding environment, as these eventually chemicals make their way into the soil and water.

As an example, a microfiber-based window cleaning system, such as the Unger Stingray, can decrease the use of chemicals by as much as 39% when compared to a window cleaning solution that relies on the traditional cloth and spray bottle. As a floor cleaning solution, a microfiber mop uses $.50 of cleaning solution per 100 rooms, while conventional wet loop mops use $11.55 of cleaning solution per 100 rooms.

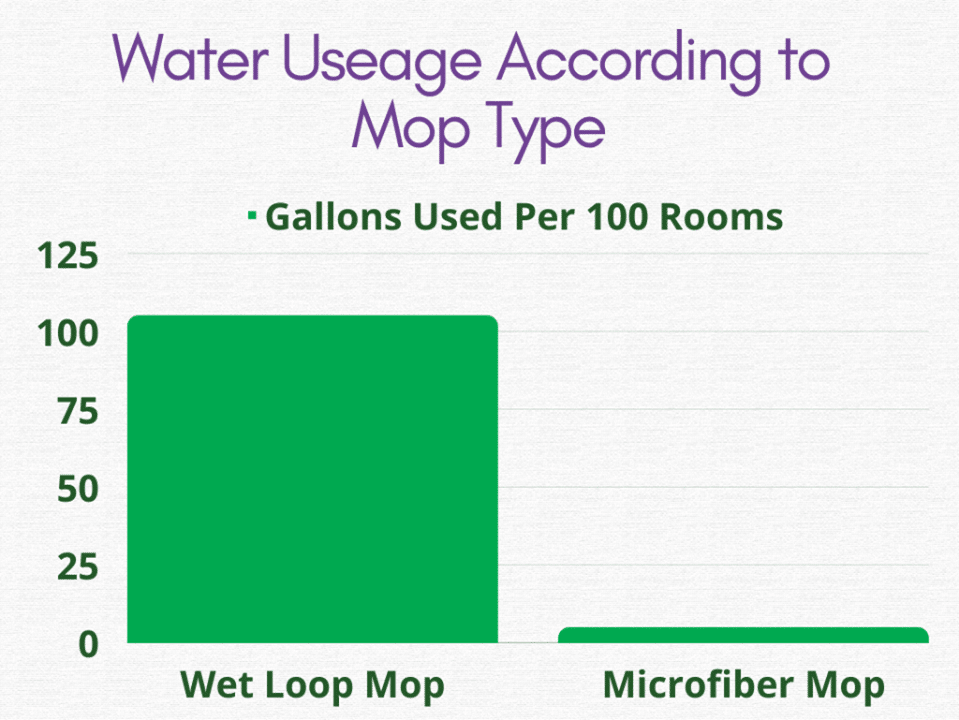

Microfiber also lessens the overall environmental impact of cleaning by conserving water use. According to the EPA, conventional Wet Loop Mops use 105 gallons of water per 100 rooms whereas a microfiber mop uses only 5 gallons per 100 rooms.

Sustainability and Pure Water Cleaning

Like microfiber, one of the eco-friendliest features of pure water cleaning is that you can often forego using chemical cleaners thanks to the science behind pure water.

Pure water is created through one of two water purification processes, or a combination of the two: reverse osmosis and deionization. Reverse osmosis is the process of removing impurities (ions) from tap water by forcing it through a filter. Deionization is the process of removing positive metallic ions (impurities) and replacing them with hydrogen and hydroxyl to form pure water. Using either or a combination of these processes removes up to 99% of all the sediment and minerals from the water to create impurity-free pure water.

When cleaning with pure water, the water immediately wants to try and return to its natural state (one with impurities) when it hits the window surface. To make this happen, the pure water seeks out dirt, dust and other particles to which it can adhere. Once the two elements meet, they are bonded together for easy removal during the rinse step of the process, all without the use of chemical agents! Avoiding chemical use keeps any runoff from outdoor window cleaning safer as it enters the sewer system and makes its way back into your water supply.

Additionally, using accessories such as a window cleaning brush, along with a pure water cleaning system can reduce the cleaning time required to complete the job and subsequently conserve water.

A Better Way to Green Commercial Cleaning

Some improvements to get you closer to a greener way of cleaning may be simple and inexpensive to implement, while others may be more complex and require assistance from experienced commercial cleaning industry professionals. Unger has over years 50 of history in providing innovative cleaning equipment that help you clean faster and safer, and in ways that minimize the environmental impact. If we can help you assess the impact of implementing microfiber and pure water cleaning technologies in your facilities, contact us.