From Cobweb Duster to Light Bulb Changer, High Ceiling Cleaning Equipment that Keeps Your Feet on the Ground

Employees in the cleaning industry face a multitude of safety hazards from exposure to harsh chemicals every day, to repetitive stress injuries, to performing cleaning tasks that can potentially cause greater injury if not performed correctly. Even though OSHA standards and guidelines exist to minimize these hazards and improve worker safety, falls continue to be one of the most common causes of serious work-related injuries and deaths. For facility managers, building service contractors and employers, this means prioritizing worker safety, specifically as it relates to high ceiling cleaning equipment that forgoes traditional requirements for ladders, lifts and scaffolding.

Fall Risk and Prevention

Falls are the leading cause of ladder-related injuries followed by:

- Improperly mounting or dismounting;

- Losing one’s balance;

- Failing to set up the ladder properly;

- Over-reaching while on the ladder; and

- Mis-stepping while climbing or descending.

OSHA requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations. To protect cleaning staff and others from fall injuries, OSHA mandates that employers:

- Guard every floor hole into which a worker can accidentally walk (using a railing and toe-board or a floor hole cover);

- Provide a guard rail and toe-board around every elevated open sided platform, floor or runway;

- Regardless of height, if a worker can fall into or onto dangerous machines or equipment (such as a vat of acid or a conveyor belt) employers must provide guardrails and toe-boards to prevent workers from falling and getting injured; and

- Other means of fall protection that may be required on certain jobs include safety harness and line, safety nets, stair railings and hand rails.

Fall Injuries in the Workplace

According to the World Health Organization, the United States leads the world in ladder deaths. Each year in the U.S., there are more than 164,000 emergency room-treated injuries and 300 deaths caused by falls from ladders. Unfortunately, serious injuries can be sustained from even a short fall. In fact, most ladder deaths are from falls of 10 feet or less.

In the workplace specifically, falls involving ladders are a leading cause of workplace injuries according to a NIOSH study. The study found that ladders are involved in 20% of fall injuries among workers.

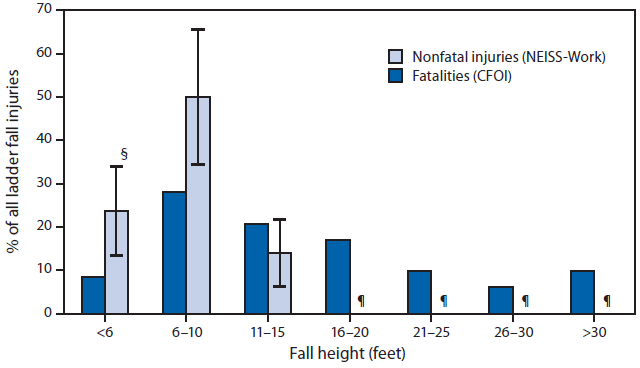

The following image shows the percentage of ladder fall fatalities and nonfatal ladder fall injuries treated in emergency departments, by fall height (when documented).

The Problem with Ladders

One of the biggest challenges with ladders is that fall prevention primarily relies on the proficiency of the person using the ladder. The first step in using a ladder is visually inspecting it, and not simply assuming that it is ready for use. When inspecting the ladder, the person should look for:

- Structural damage, split/bent side rails, broken or missing rungs/steps/cleats and missing or damaged safety devices

- Grease, dirt or other contaminants that could cause slips or falls

- Paint or stickers (except warning or safety labels) that could hide possible defects

Once inspected, the user is then responsible for:

- Positioning the ladder on a non-slippery, stable surface

- Locking ladder spreaders

- Staying off the top step or top cap

- Abiding by the ladder’s load capacity

- Minimizing ladder use away from high-traffic areas

- Not extending past the ladder side rails

- Keeping the ladder at a safe distance from electrical wiring/equipment

With the responsibility lying with the user and their best judgement, facilities should not take the decision lightly as to when to employ ladders when executing facility cleaning tasks. When a task requires staff to reach a high access area, facilities should consider the following to determine if a ladder is the best high ceiling cleaning equipment for performing the job effectively, and more importantly, safely. Ask these questions before an employee uses a ladder for high access cleaning:

- Does staff need to carry heavy items on the ladder?

- Will a longer ladder be required and therefore increasing the instability?

- How long will the employee be working from the ladder?

- Does the worker need to reach or strain to access hard to reach areas?

Even with proper visual inspection, practice, and training, any of the above considerations can contribute to ladder falls and OSHA violations. OSHA penalties vary depending on the citation, but in general can exceed $13,000 per violation—and as much per day for each day the issue goes uncorrected. The fine for a willful or repeated violation can potentially increase to 10 times as much. And this is only your direct penalty. Add in indirect costs associated with ladder falls, such as worker compensation claims, lost productivity due to injuries, and legal and compliance fees, and your overall penalty is significantly more costly than investing in the proper commercial cleaning equipment designed for fall prevention.

High Ceiling Cleaning Equipment

There’s no getting around the fact that most buildings have hard to reach areas that would typically require a ladder, lift or scaffolding, all of which are not only dangerous but also cumbersome. To reduce the possibility of repetitive stress injuries and falls when the jobs reach upwards of 20, 30, or 65 feet, cleaning staff have to keep their feet safely planted on the ground.

With the following high access cleaning tools, staff can clean and maintain a variety of surfaces previously thought to be beyond their reach without the use of a ladder.

- Telescopic Aluminum Poles

Telescopic poles are the ideal equipment for professional cleaners and custodial staff to work from the ground safely. Aluminum telescopic poles come in numerous lengths, allowing access to areas up to 30 feet high. These extension poles can be used with a variety of cleaning attachments, such as brushes, squeegees and dusters, to quickly transform it from a telescopic pole to other convenient, easy to use equipment, such as a:- Commercial cleaning brush: Whether cleaning outdoor windows with pure water or powering through high access indoor surface scrubbing, angled bristles reach corners and edges while ergonomic handles reduce bending and over-reaching.

- Light bulb changer: Insulated designs keep custodians safe from heat while changing bulbs, and long pole handles keep feet on the ground and off dangerous ladders and lifts.

- Cobweb duster and ceiling fan duster: Find a dust remover of every material, from a microfiber duster to lambswool duster to clean ceilings, moldings and corners without the risk of falling.

- Waterfed Poles

You can also wash windows safely from the ground. With waterfed poles you can safely clean outdoor windows and glass without ever leaving the ground. Light weight telescopic poles and handles give access to high windows up to five stories, while avoiding the danger of slipping on wet ladder steps while washing windows.

Extend Your Reach and Your Clean

As long as facilities need to be cleaned, fall safety and prevention requirements are not going anywhere, leaving facilities with the ongoing task of carefully cleaning high access areas and minimizing the use of ladders or lifts. However, if you do need to use a ladder, use it safely. March is National Ladder Safety Month and an opportunity to re-evaluate your high ceiling cleaning equipment and ladder usage.

Unger offers a diverse selection of window cleaning tools, dusters, brushes and bulb changers that combine with our line of telescopic and waterfed poles to easily reach high access areas. If we can show you how to keep cleaning while staying on the ground, please contact us.