Understanding Water Purification Technology: RO and DI Systems

Once you’re on board with the value of pure water window cleaning, the next step is to evaluate the different purification technologies to determine the best solution for your volume of work and water quality requirements. While RO (reverse osmosis) and DI (deionization) systems differ regarding their technologies, they are both designed to remove impurities from ordinary tap water and produce pure water. Pure water is considered 100% demineralized and desirable for window cleaners who want to have the results of their labor be a streak and spot-free appearance.

There’s no right or wrong choice when selecting which commercial window cleaning solution is right for you. As with any commercial cleaning equipment investment, your decision depends on several factors specific to your job and facility.

The Science Behind an RO Water Purification Technology

In its natural state, water contains impurities. In order to deem the water “pure,” you have to create it through one of two water purification processes, or a combination of the two: reverse osmosis and deionization.

In its natural state, water contains impurities. In order to deem the water “pure,” you have to create it through one of two water purification processes, or a combination of the two: reverse osmosis and deionization.

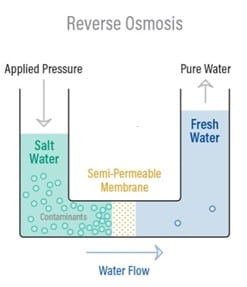

Reverse osmosis is the process of removing any impurities (ions) from the water by forcing it through a filter, or a membrane. Think of this membrane as a coffee filter. Using pressure to force water across a membrane, the impurities (coffee grinds, in this example) are left on one side of the membrane and the purified water (or, coffee) on the other side, free to move through your

(Image Source: https://puretecwater.com/reverse-osmosis/what-is-reverse-osmosis)

How the Science Behind DI Water Purification Technology Differs

Deionization is the process of removing ions (impurities) from water by exchanging positive hydrogen and negative hydroxyl molecules for the positive and negative contaminant molecules in water.

In a DI window cleaning system, the core component is the ion exchange resin filters. These filters contain specialized resin beads that attract and remove dissolved minerals and impurities from the water. The first filter in the system is typically a cation exchange resin, which removes positively charged ions, including calcium, magnesium, and other metals. The second filter is an anion exchange resin that targets negatively charged ions, such as nitrates, sulfates, and other dissolved solids.

Like the RO purification system, in the DI system, the purified water is then available to move freely through your waterfed pole system.

Choosing the Best Pure Water Window System for the Job

Ultimately, the choice between an RO and DI system and for your water purification technology depends on multiple factors:

- Water Quality Requirements:

The total dissolved solids (TDS) reading in water is a measure of the combined content of all substances dissolved in it, typically expressed in milligrams per liter (mg/L) or parts per million (ppm). TDS is an important parameter for determining water quality, especially when it comes to determining water hardness.

The presence of calcium and magnesium ions in the water is primarily what causes water hardness, which is usually classified into the following categories based on TDS levels:

Soft water: 0-60 mg/L or ppm TDS

Slightly hard water: 61-120 mg/L or ppm TDS

Moderately hard water: 121-180 mg/L or ppm TDS

Hard water: 181-300 mg/L or ppm TDS

Very hard water: Above 300 mg/L or ppm TDS

Water with a TDS reading above 300 mg/L (or ppm) is considered very hard water

Consider the desired level of water purity for your window cleaning needs and if the hardness level of your water source is anywhere between 250 and 400+. If you require the highest level of purity and want to minimize the risk of streaks or spots on windows, an RO system may be better. RO systems are highly effective at removing a wider range of impurities, including dissolved salts, minerals, and larger particles.

If you have soft-medium water (<100 to 250 TDS levels), a DI only unit can get the job done. DI systems primarily focus on removing ions from water and will clean windows effectively. However, with higher TDS levels, resin in the DI system will be used up more quickly as opposed to an RO system. Often DI cleaning systems are used as a final polishing step after the initial cleaning.

- Budget:

Generally, an RO system has a higher upfront cost compared to a DI system, mostly due to the more complex system for RO cleaning. While the lower initial cost of a DI system may be a compelling purchasing point, there are ongoing expenses for resin replacement or regeneration. Click here to calculate the cost savings when using a pure water window cleaning system.

- Water Production Rate:

Consider the required water production rate for your higher-story window cleaning. RO systems can be slower compared to DI systems, although some RO systems come with a booster (or pump) to avoid this challenge.

As water flows through the system’s membranes, there is a natural pressure drop due to the filtration process. A booster pump helps overcome this pressure loss, ensuring that the water maintains consistent pressure as it passes through the filtration membranes. This consistency is essential for achieving uniform cleaning results across different windows.

In the case of low water pressure from the main supply, the booster pump compensates by increasing the pressure to the required level for the RO system to function properly.

- Wastewater Considerations:

RO systems generate wastewater as a byproduct of the filtration process. The exact ratio of purified water to wastewater depends on the specific RO system and its configuration. When using a DI system, wastewater considerations are typically different. Unlike RO systems, DI systems do not generate wastewater as a byproduct of the filtration process. The DI filters selectively remove dissolved minerals and impurities from the water without producing any wastewater.

- Practicality and Convenience:

DI systems tend to be more compact and streamlined compared to RO systems. This is because DI systems require fewer components in the filtration process. In contrast, RO window cleaning systems are often larger and more complex as they utilize a multi-stage filtration process involving sediment filters, carbon filters, and a semi-permeable membrane.

The size and design of both DI and RO systems can vary depending on the specific needs and requirements of the cleaning operation. When selecting a system, it is essential to consider the available space, water demand, portability, and specific filtration needs to choose the most suitable option for your outdoor window cleaning requirements.

See Our Water Purification Technology in Action

Selecting which water purification technology is right for you depends on your specific cleaning needs, water quality requirements, and preferences. To see Unger’s pure water cleaning systems in action, Watch These Product Videos.

These window cleaning systems are the perfect fit for professional window cleaners that demand the best for their window washing services. Engineered to be portable, easy to operate and extremely efficient, Unger HydroPower systems are at the cutting-edge of pure water innovation for the cleaning industry.

Do you require top-quality water for optimal results? Learn more about Unger’s Pure Water Cleaning Systems.