Are Your Floor Cleaning Efforts Enhancing or Hurting Your Floors’ Slip Resistance?

Wet and slippery floors pose a major safety and liability concern to facility employees and occupants. So much so that according to a report by the Agency for Healthcare Research and Quality, falls are the most common cause of injuries treated in the emergency department.

Falls do not only create a vulnerability in terms of safety, but also for worker productivity. In fact, falls represent the primary cause of lost days at work and are the leading cause of workers’ compensation claims. Falls can also lead to inefficiencies throughout the organization as it scrambles to correct the situation.

To minimize the fall risk associated with slippery floors, it’s important to first understand how to measure the slip resistance of floors and then evaluate how your floor cleaning procedures and equipment are impacting the risk. Through this evaluation you may be surprised to learn that you actually may be using more water than necessary to clean your floors and inadvertently creating a greater risk for falls.

Regulation on the Slip Resistance of Floors

Regulations are in place to advise on the slip resistance of floors. The United States Department of Labor’s Occupational Safety and Health Administration (OSHA) has general requirements for walking-working surfaces. These include:

- Floors must be maintained in, to the extent feasible, a dry condition.

- When wet work processes are in place, there must be drainage and, to the extent feasible, dry standing places, mats, etc.

- Walking-working surfaces must be free of leaks, spills, snow, ice and other hazards. If hazards can’t be immediately eliminated, there must be guards in place to prevent workers from using the walking-working surface until it’s corrected.

- Walking-working surfaces must be regularly inspected and maintained to be in a safe condition.

The Americans with Disabilities Act also has accessibility standards that mandate that accessible ground and floor surfaces be slip resistant.

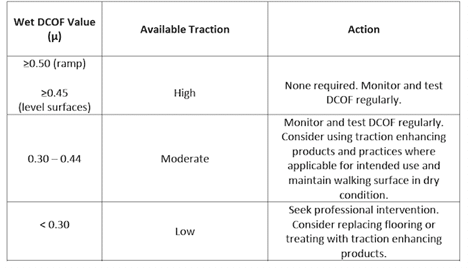

At present, OSHA does not have an official slip test or safety standard for flooring, however, it recommends a slip resistance static coefficient of friction (COF) of 0.5 In 2020, the National Floor Safety Institute (NFSI) B101.1 and B101.3 wet Coefficient of Friction (COF) test methods defined the term “slip resistant” to be a walkway surface which when tested per these standards is “Moderate to High-Traction.” Looking at the Wet Dynamic Coefficient of Friction (DCOF) standard, Moderate Traction walkways have a DCOF of 0.30 to 0.44, while High-Traction walkways have a wet DCOF level of 0.45 or greater. (See Table Below)

There’s also no regulation in the flooring industry that requires manufacturers to test the slip resistance and/or label the results of their products. This lack of upfront visibility can result in inadequate flooring selection for a facility’s needs. While OSHA recommends textured, serrated or punched slip resistant flooring material to provide additional slip resistance, there’s no legal requirement to install this type of flooring.

Measuring Floor Slip Resistance in Your Facility

Testing a floor’s slip resistance provides valuable information and confirmation that walkways comply with the national standards. Not only is testing best practice, but it’s also the law. Section 302.1 of the Americans with Disabilities Act (ADA) requires that floor and ground surfaces be “stable, firm, and slip resistant…” The International Building Code (IBC) and the National Fire Protection Association (NFPA) 101 Life Safety Code all mandate that walkways be slip resistant.

The NFSI has approved portable, easy to use test devices, called tribometers, that facilities use to measure the slip resistance of floors by taking COF measurements. You can find a list of these NFSI approved tribometers here.

Floor Cleaning Mistakes that Jeopardize Slip Resistance

Despite the slip resistance of the flooring material itself, custodial staff and floor cleaners can also contribute to the risk of slip and fall accidents. The application of the wrong floor cleaning product, incorrect application of the product or the overuse of water during the cleaning process increases the risk of leaving a slippery floor behind.

According to research reported in Cleaning and Maintenance Magazine, the following floor cleaning practices can lead to unsafe floor surfaces:

- Using too little or too much of a floor care product

- Using the wrong cleaner for a specific surface

- Not following floor cleaner instructions

- Not rinsing the floor cleaner, if required

- Not brushing the floor thoroughly, if required

- Not adhering to a routine floor maintenance schedule

The research also shows when surface grease bonds with residual soap and builds up, that could result in a slippery soap film on seemingly clean and dry floors. Contaminants like mineral deposits and soil, as well as fragrances in cleaning products, could also cause the film to become polymerized. This increases the slippery factor of the flooring, as well. So, while to the naked eye a floor surface may look dry and clean, the invisible polymerized films may create a slippery wax-like coating over time.

Floor Care Recommendations to Reduce Slip and Fall Accidents

Proper floor cleaning can go a long way in preventing slip and fall accidents while also delivering the highest level of clean. A routine floor cleaning procedure supported by the right products and defined emergency protocols can help protect your organization from putting occupants at unnecessary risk. Floor cleaning best practices include:

- Determine how often you should clean your floors. This decision depends on a variety of factors, including the material of the floor, foot traffic and any seasonal impact on the floors.

- Train employees. Educate your workforce on the seriousness of slip and fall accidents and precautions they can take to avoid posing additional risks. Train employees on what they should do when hazards emerge and who to inform when floors are slippery.

- Clean spills up quickly. The 2021 “Materials” study confirmed wet floors typically pose a more significant slip hazard compared to dry floors. When surfaces become wet, slick or oily, immediately alert those in the area to the hazard, and remove it quickly.

- Use floor mats if necessary. Supplemental items like floor mats can provide an additional layer of slip resistance in high-risk areas. You can add these to flooring that’s likely to get wet or slick, or in areas where there’s a high level of foot traffic, like a hallway or entrance.

- Use floor cleaning tools designed to limit slipperiness. The tools and products you use can dramatically affect the slip resistance of your environment. Look for floor care products and equipment that:

- Use Less Water and Dry Floors Quicker

Microfiber mops require less water than traditional cotton string mops, using 10 to 30 times less liquid. Not only does this result in a significantly lighter mop, but it also means that with less water, floors dry faster, creating a safer environment and reducing the potential for slip and fall accidents.Microfiber mop pads hold much less solution than a string mop yet is still very efficient at cleaninglarge square footage. With less solution required, the mop bucket can hold less water. - Clean Floors Faster

Many factors go into the speed of cleaning floors, including the ergonomic design of the mop handle, the weight of the wet mop, and whether or not the floor mopping system includes a scrubber and wringer onboard. Having the right commercial floor cleaning tools lends itself to a more efficient process that minimizes the cleaning time. - Remove More Surface Microbes & Debris

Microfiber floor mops help reduce the risk of residue and film forming as they remove more debris and microbes from the floor when compared to cotton When combined with a dual chamber mop bucket – one that isolates dirty water from clean water – you can actually clean with clean water, leaving floors cleaner than if using a single chamber bucket.

Your Floor Cleaning Equipment Choices Can Enhance Slip Resistance

Using less water in the process, executing protocols faster and using floor cleaning tools designed to reduce water and debris left on surfaces can aid your facility in minimizing slip and fall accidents.

If you want to improve your floor cleaning experience to complement the slip resistance of your flooring, Unger’s line of commercial floor cleaning products can help. We’re committed to keeping facilities and the people within them safe.